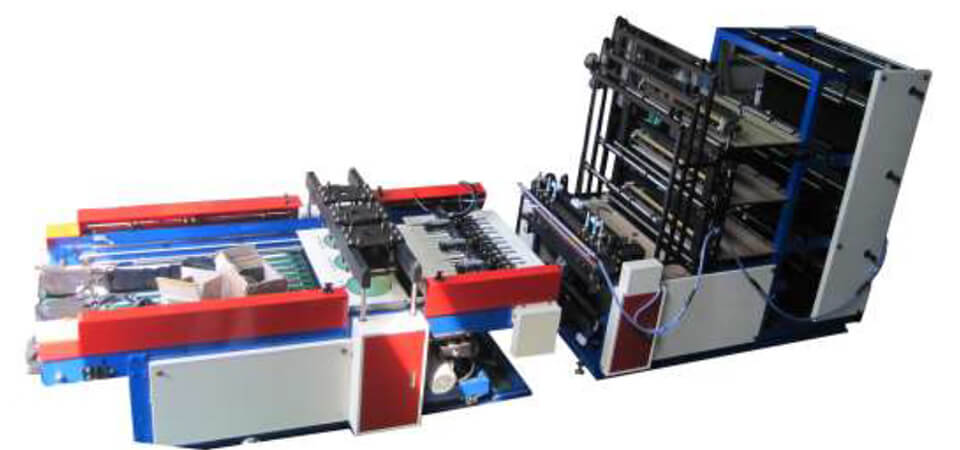

Bottom Seal and Cutting Machine (Automatic)

Fully Automatic Shopping Bag Making Machine (PM-AP1006)

Plastmach supply Automatic high speed bag making machines designed and manufactured in South Korea for high efficiency.

The high-speed tech savvy, bottom seal bag making machine uses a tubular roll of different sizes to make regular bottom seal bags and with other various attachments. LDPE, HDPE, PP materials can be used on this machine.

There are various models differentiated by web width. This way one can select as per customized requirement.

Features

3 Line Punching

3 Line x 2 Decker = 6 Line Infeeding Unit

Bag Shapes

Specifications

| Model | PM-AP1006 |

| Bag Size | 900 mm * 2 line, 430 mm * 4 line, 280 mm * 6 line, max. 700 mm length |

| Applicable Film | HDPE, PE, PP etc. with 6 ~ 50mic thickness |

| Capacity | 120 cycles/min * 6 line = 720 bags/min |

| Produced Bag | T-shirt Bag & Open Bag |

| *** Main Feeding Roller Width – According to Customer’s need *** | |

Fully Automatic Shopping Bag Making Machine (PM-AP1009 (1080bags/min))

Features

3 Line Punching

3 Line x 3 Decker = 9 Line Infeeding Unit

Bag Shapes

Specifications

| Model | PM-AP1009 (1000 mm Feeding Roller) |

| Bag Size | 900 mm * 3 line, 430 mm * 6 line, 280 mm * 9 line, max. 700 mm length |

| Applicable Film | 6 ~ 50 mic |

| Capacity | max. 120 cycles/min * 9 line = 1080 bags/min |

| Produced Bag | T-shirt Bag & Open Bag |

| *** Main Feeding Roller Width – According to Customer’s need *** | |

Fully Automatic Shopping Bag Making Machine (PM-AP1710 (1200bags/min))

Features

5 Line Punching

5 Line x 2 Decker = 10 Line

Bag Shapes

Specifications

| Model | PM-AP1710 (1700 mm Feeding Roller) |

| Bag Size | Max. 250 mm width * 10 line, max. 500 mm length |

| Applicable Film | 6 ~ 50 mic thickness |

| Capacity | Max 120 cycles/min * 10 line = 1200 bags/min |

| Produced Bag | T-shirt Bag & Open Bag |

| *** Main Feeding Roller Width – According to Customer’s need *** | |

Applications